There are two major ways to add value to waste materials and transform them into raw materials for new products.

1. Waste material can be used as a substitute for natural raw materials in SCG’s product manufacturing process.

SCG adopts the recycling approach by using the waste from operations within SCG and external sources from partners as replacement for raw materials and increasing proportion of recycled materials to generate standard-quality product while committing to optimal and maximized resource value. SCG is putting its best effort to expand the proportion of recycled materials used in the production of the entire product line as follows:

a. Thermal insulation: recycled materials (75-80% from recycled glass bottles) are used as replacement for natural sand.

b. Tiles: recycled materials (7-12% from soils, ceramic scraps) are used as replacement for natural soil.

c. Sanitary ware: recycled materials (14-19% from soils, ceramic scraps) are used as replacement for natural soil.

d. Faucet: recycled materials (27-32% from brass scraps, copper scraps) are used as replacement for natural materials.

e. Synthetic wood: recycled materials (6-11% from calcium dust and synthetic wood scraps) are used as replacement for natural materials.

f. Roof:

- Concrete roof: recycled materials (17-22% from fly ash, stone dust and roof tile scraps) are used as replacement for natural materials

- Ceramic roofs: recycled materials (18-23% from soils, sediments and roof tile scraps) are used as replacement for natural soil.

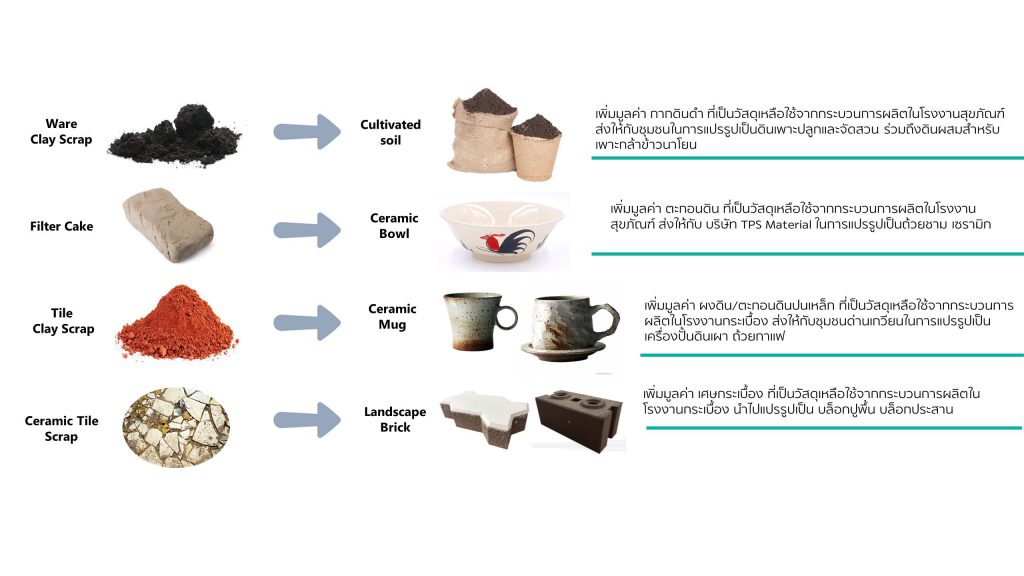

2. Waste materials from the SCG production processes are offered to communities

for extended usage in agriculture or other community enterprises’ product development with the top priority of material safety and community sustainable development.

a. Soil Mixes and Topsoil for Organic Rice Parachuting

The leftover soils from the production process of sanitary ware and floor tiles and wall tiles are converted into garden soils for planting. The approach is to add value to soils and remaining soils from production process while and creating jobs for communities in Ratchaburi province where the plants operate. The communities are Champakpaew community in Kaeng Koi , Kokyae Community in Hin King and Hin Kong municipality.

b. Paving Blocks

Use unapproved and substandard ceramic tiles as raw materials for producing paving blocks and using in gardening

c. Ceramic Dishware (Chicken Brand)

Use sediments from sanitary ware production as raw materials for producing dishware

d. Dan Kwien Coffee Mugs

Use sediments from ceramic tile production as raw materials for producing coffee mugs and pottery products at Dan Kwian Pottery Village.