Accelerate Circularity, Accelerate Innovation, and Accelerate Digital Technology

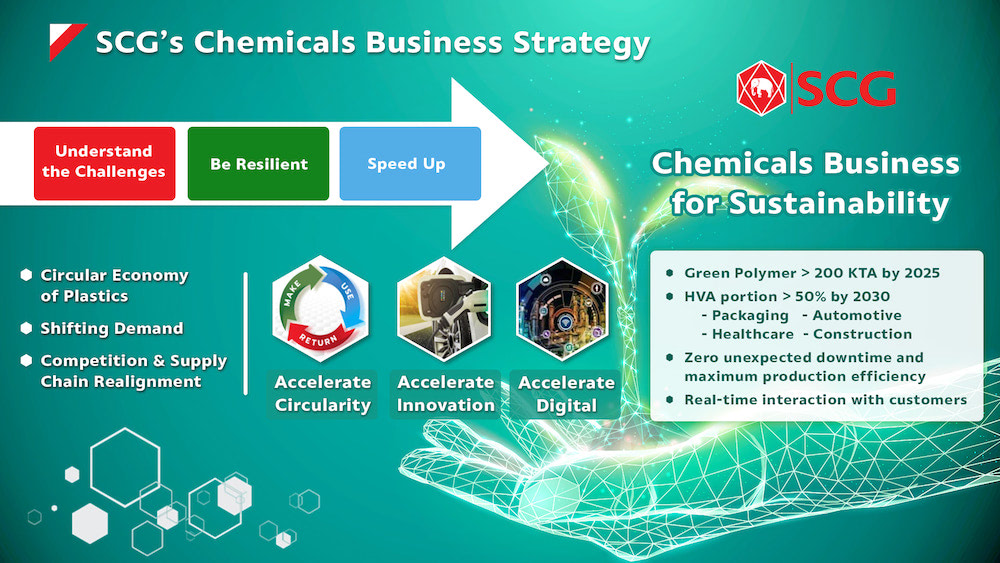

Chemicals Business, SCG, announced strategic business direction for 2021 toward a “Chemicals Business for Sustainability.” SCG has set the target to achieve green polymer sales volume of 200,000 tons by 2025, and to increase the proportion of sales of HVAs (High Value-Added) products by 50% within 2030. Chemicals Business outlined three key business strategies: Accelerate Circularity, Accelerate Innovation and Accelerate Digital Technology to gain higher competitive edge in the global stage, and to build long-term growth with sustainable development.

Mr. Tanawong Areeratchakul, President of Chemicals Business, SCG, disclosed the 2021 business direction, “Over the past year, Chemicals Business, SCG, had proactively adapted itself in several areas amid the COVID-19 pandemic to keep operations running smoothly. One of our major projects is the olefins plants’ capacity expansion project or MOCD, which progresses as planned and is expected to begin commercial operation by the beginning of the second quarter. The operation will add olefins production capacity of 350,000 tons per year.”

“The year 2021 will bring new challenges to the petrochemical industry, which requires short-term and long-term strategic changes. We foresee three major challenges. First is Circular Economy for Plastics, especially post-consumer plastic management, which has become a priority for brand owners and consumers in a global shift towards sustainable consumption. The second challenge is Shifting Demand brought about by the COVID-19 pandemic, which has contributed positively to industries like logistics packaging or plastics for medical equipment. We expect during the post-COVID-19 economic recovery, some industries which have suffered a dip in demand such as cars, electric appliances, or durable products will bounce back while medical and healthcare will enjoy rising demand in the long run. Meanwhile, Competition & Supply Chain Realignment will be more intense, partially because of the shift of trade flows amid the ongoing trade war.”

“To tackle new business challenges and to meet Sustainable Development Goals set by the United Nations and ESG (Environmental, Social, Governance) targets, Chemicals Business, SCG, strives to become ‘Chemicals Business for Sustainability’ with the aim of achieving 200,000 tons of Green Polymer sales volume by 2025 and increasing the proportion of HVA sales to 50% within 2030 while integrating digital technology to enhance operations throughout the supply chain. Our three strategic plans are as follow:

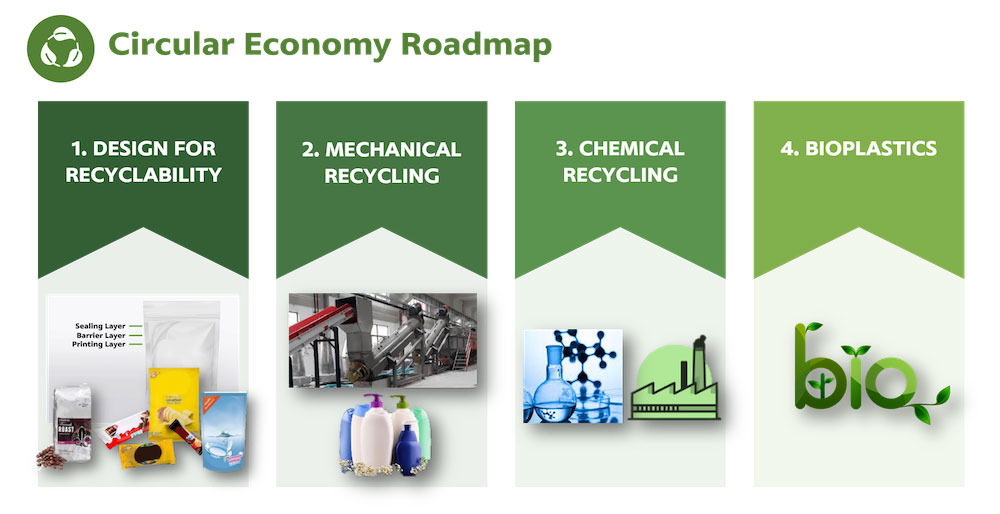

- Accelerate Circularity: The plan is to promote resource use efficiency and mitigate global warming. Chemicals Business will offer solutions catered to the needs of brand owners and eco-conscious customers. The circular economy roadmap will drive this strategy covering the supply chain in four areas:

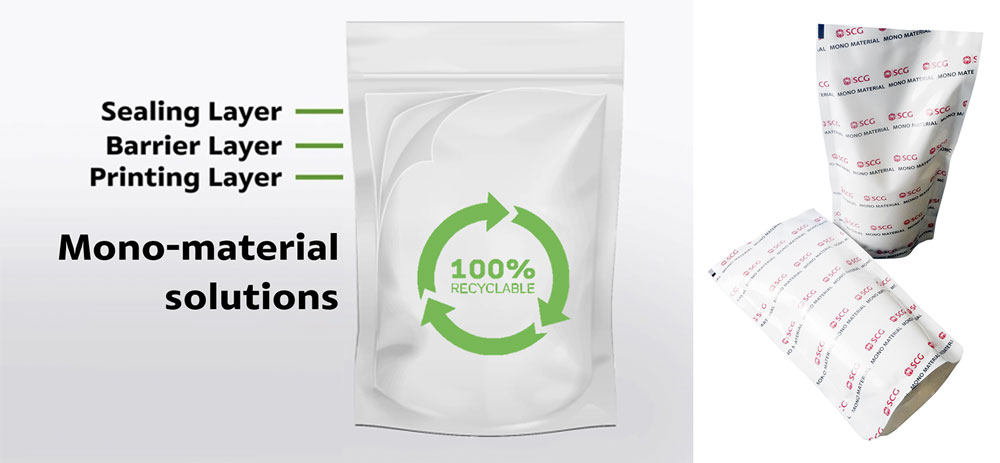

1.) Design for Recyclability: Introduce the design approach conducive to 100% recyclability while maintaining all other properties. Examples include the development of mono-material plastic packaging where the packaging layers are made of the same material to facilitate ease of recycling. SCG has developed “Medium Barrier Packaging” as a packaging solution equipped with moderate permeability, replacing nylon in the mid-layer for dishwashing liquid pouches, liquid soap bags, rice bags, or vacuum packaging such as sausage bags. The solution enables full recyclability and will help to improve post-consumer management. The solution is currently in the development process done in conjunction with several brand owners.

2.) Post-Consumer Recycled Resin (PCR): Develop HDPE PCR under the brand “SCG Green PolymerTM” for packaging of household and consumer products. The strategy aims to reduce environmental impacts. Also, SCG is developing an additive called PCR Booster to enhance packaging quality which allows a higher proportion of PCR ingredients in the production process while maintaining the same performance characteristics.

3.) Chemical Recycling: Thanks to our cutting-edge technology and eco-friendly process, it will be possible to recycle used plastics into recycled feedstock for petrochemical plants. The technology can also turn post-consumer plastics into raw materials to produce food-grade products. SCG has established Thailand’s first demonstration plant in Rayong. The demonstration unit will have a production capacity of approximately 4,000 tons per year, where a capacity expansion plan is in sight. Compared to waste incineration or landfills, this recycling process leaves a much less carbon footprint.

4.) Bioplastics: The process is in the research and development phase, and SCG is currently engaged in negotiations with like-minded partners.

- Accelerate Innovation : Chemicals Business has consistently developed HVA products and services with the core focus on four industries: packaging, healthcare, automotive, and construction. The company has developed innovations in the forms of in-house and open innovation with its R&D networks such as educational institutions, leading global research institutes in Thailand, Asia, and Europe. This year, Chemicals Business, SCG, has allocated 1,600 million Baht for R&D. Besides, SCG has established Thailand and ASEAN’s first i2P Center (Ideas to Products) since 2019 as a platform solution for material selection, design, and process. The center offers a product prototype development unit that inspires customers and brand owners. The center also facilitates the acceleration of innovation and product development at approximately 3x the normal pace.

- Accelerate Digital Technology : Digital technology is implemented to enhance business capabilities with regards to speed and efficiency. SCG has strengthened the organization with digital technology integration throughout our supply chain. The company also introduces the Single Data Platform to engage all relevant stakeholders with one dataset in real-time. Examples include the use of digital technology in the procurement process to enable increased efficiency and alignment with market situations. Digital technology is also harnessed to increase operational reliability. This is done by using a predictive model to alert machine malfunctions before the damage occurs and using AI simulation for production process improvements. SCG also introduces Digital Commerce Platform or DCP to connect purchase orders to the supply chain data management. This allows customers to track their orders from anywhere and at any time, thereby reducing process time by 70%.”

With three strategic plans: Accelerate Circularity, Accelerate Innovation, and Accelerate Digital Technology, SCG is fully equipped to deliver solid and sustainable growth whilst also meet Sustainable Development Goals and ESG targets. Commitment to innovations and the solutions SCG delivers will help improve the quality of lives of the people, communities, society, and the environment in a sustainable manner. SCG stands ready to cooperate with all sectors to bring about mutual benefit and sustainable growth.

บทความนี้มีประโยชน์หรือไม่ ?

Average rating 5 / 5. Vote count: 4

No votes so far! Be the first to rate this post.