GREEN

SOLUTIONS

1. CPAC Green Solution

Integrated digital technology-enabled green construction innovations that elevate Thailand’s construction industry

CPAC Drone Solution

CPAC BIM

Providing an overview of every step of the construction, this digital technology helps ensure design accuracy and control the quality of the entire construction project from the designing process to the detection of potential errors. It is enhanced with digital construction technologies for project management, which ensure that all related parties, from manufacturers, designers, contractors, project managers, and customers are on the same page during the design, construction, and post-construction stages and enable them to track the progress and keep the construction on track. After the project delivery, the data can be used in building management. This innovation also helps to lower rejects and repetitions in construction, which in turn reduces wastage of resources, including time, labor, and material scraps, by 5-15% depending on project types.

CPAC 3D PRINTING SOLUTION

The design and 3D printing innovation for eco-friendly construction affords more design freedom as it can produce curve building features and textured surfaces as desired. Exclusive to SCG, the use of a cement 3D printer not only helps shorten the construction time and lessen material scraps on the construction site but is also eco-friendly and applicable to construction works, decoration, furniture building, and landscape decoration, such as in the production of artificial corals. The solution can be deployed on-site and off-site. In wall construction, the technology can shorten the construction time by 30%, reduce labor needed by 50%, and lower material scarps generated at the site.

2. CPAC Bridge Solution

Innovation of the construction of Thailand and ASEAN’s thinnest concrete bridge

The construction of “CPAC High-Strength Fiber-Reinforced Concrete Bridge” with UHPC (ultra-high performance concrete) helps address engineering problems of an arch bridge, which has a height limit due to the high thrust force acting on the foundation and thus can significantly increase the construction cost, by building cantilevers from both ends instead to eliminate the thrust force and using UHPC to support the bending force in the cantilevers. As part of the project, concrete mixing machines and plasticizers were developed, and a bridge health checkup system was designed and installed to monitor the structural integrity through the lifespan of the bridge. This solution thus represents a modern bridge construction trend that centers around green and low-carbon construction and is made eco-friendly across all stages to foster sustainable growth in accordance with the ESG approach.

Additional information : https://web.cpac.co.th/micro/cpac-green-solution/th/home

3. Low-carbon products with circular innovation

Low Carbon Concrete Solution – An eco-friendly alternative

CPAC Low Carbon Concrete (Hybrid Cement)

is a concrete formulation based on hybrid cement rather than Portland cement for increased eco-friendliness and releases at least 3.9 kg/m3 less greenhouse gases (CO2) in production. It offers a superior or equivalent level of strength, durability, and resistance to compression to regular Portland cement.

*Compared to Type 1 Portland concrete at the same level of compression, equivalent to planting four trees for every 10 cubic meters of concrete used.

CPAC Low Carbon Concrete (PFA) makes use of fly ash in place of cement, thus reducing CO2 emissions by at least 17 kg/m3.

*Compared to regular CPAC concrete at the same level of compression, equivalent to planting at least 17 trees for every 10 cubic meters of concrete used.

*Based on BS EN 12390-8 water permeability testing in comparison to regular concrete at 240-400 kg/cm2

Additional information : https://web.cpac.co.th/en/product/416/concrete-low-carbon

4. SCG Green Choice Products and Services

As global warming is a major crisis that everyone recognizes and is working to solve, consumers are placing greater emphasis on selecting eco-friendly and energy-efficient products. To contribute to such efforts, SCG has launched the SCG Green Choice label, which helps consumers identify and choose green products and services by SCG with greater ease. This green label, thus, serves as part of SCG’s key mechanism in achieving its net-zero goal and increase consumer participation in fostering a sustainable world. Data has shown that consumers have paid particular attention to the green label and increasingly opted for SCG Green Choice products and services.

At present, a total of 232 products and services are available under SCG Green Choice, and the sales in the first nine months of 2022 amounted to THB 223,019 million. The current goal is to accelerate the development of green products and increase the proportion of sales of SCG Green Choice products from 50% to 67% of the total sales by 2030.

Products certified with the SCG Green Choice label include ventilation systems, indoor systems, SCG Hybrid Cement, SCG Solar Roof Solutions, pre-construction solutions, sanitary ware and faucets, ceramic tiles, insulation, green cartons from corrugated paper, and HDPE for film extrusion, which is composed at least 30% of recycled HDPE without compromising the strength of the resulting film. SCG Green Choice guarantees products and services with the following characteristics.

Climate Resilience : Products that make use of renewable energy and reduce energy consumption and greenhouse gas emissions

- Recovered Energy

- Renewable Energy

- Reduce Energy Consumption

- Greenhouse Gas Reduction

Circularity : Products that help achieve resource circulation

- Designed for Disassembly

- Reduce Resource Use

- Renewable Materials

- Reduce Water Consumption

- Extended Product Life

- Reusable or Refillable

- Waste Reduction

- Recyclable or Recycled Content

- Compostable

Well-being : Products that promote well-being and a healthy environment

- Health or Hygiene

- Ergonomics Product

For additional information : https://www.scgbuildingmaterials.com/th/campaign/scg-green-choice

5. “INNOVATION THAT’S REAL”

SCG Chemicals (SCGC) conducts its business alongside environmental conservation and strive to develop innovations to address global trends as well as green innovations under the overarching principles of circular economy and in line with the ESG approach of energy efficiency and greenhouse gas reduction, placing emphasis on the development of high valued-added (HVA) products and solutions to address global megatrends across five rapidly growing industries: consumer packaging, automotive, infrastructure, medical and well-being, and energy solutions, in accordance with its “Chemical Business for Sustainability” vision.

SCGC GREEN POLYMER™ – innovative eco-friendly plastic solutions that answer the increasing use of packaging by businesses and consumers and sustainable packaging trends.

SCGC develops eco-friendly plastic innovations under SCGC GREEN POLYMER™ brand for the production of greener packaging in order to sustainably minimize environmental impacts, maximize resource efficiency, and reduce greenhouse gases emission, which are a major contributor to global warming. SCGC’s goal is to increase its annual green polymer sales to one million tonnes by 2030. SCGC GREEN POLYMER™ comprises four groups of solutions:

REDUCE – Reducing Resource Consumption This solution makes it possible to produce higher quality plastic resin and reduce the thickness of the finished product without compromising its strength, thus decreasing plastic resin consumption. As the product is lighter in weight, the energy consumption during transportation and greenhouse gas emissions are reduced. Special-grade HPDE produced with SMX™ Technology can reduce the weight of bottle packaging by as much as 22% while enhancing the strength as well as resistance to impact and chemicals, thus making it ideal for a diverse range of packaging designs across household and industrial use.

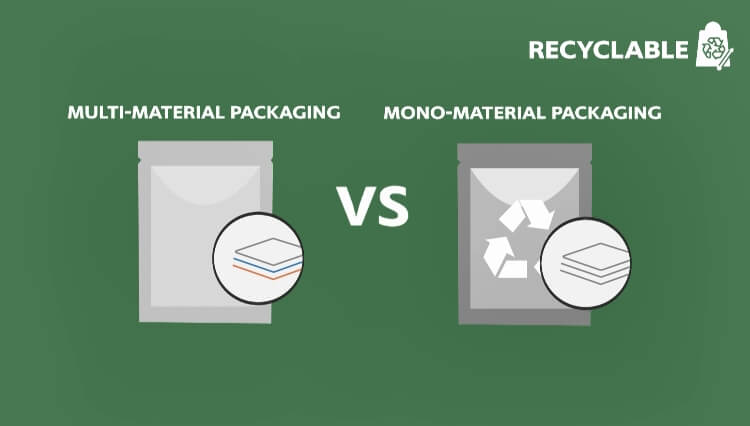

RECYCLABLE – Designing for Recyclability SCGC has developed recyclable packaging solutions for the production of mono-material PE, PP, and PO packaging that can be recycled more efficiently, thus contributing to a circular economy and environmental conservation.

ASEAN’s first barrier coating innovation to be certified by RecyClass

Because the innovative coating barrier can obviate the need to use different film layers in traditional flexible multi-material pouches, such as those used for chilled, frozen, and dry food and refill pouches for body care and detergents, it can help to produce mono-material packaging that can be recycled efficiently./p>

RECYCLE- Recirculating Resources

High Quality Post-Consumer Recycled (PCR) Resin from Mechanical Recycling

Post-consumer plastics from households are mechanically recycled and enhanced with SCGC’s proprietary formulations into high-quality HDPE, LDPE, and PP resins. The source of used plastic can also be traced, in accordance with the international Global Recycled Standard (GRS). Capable of replacing the use of virgin plastic by 25-100% and reducing greenhouse gas emissions by 70%*, the innovation has led to partnerships with world-class companies, such as the development of high quality HDPE PCR for Sunlight bottles in collaboration with Unilever.

*The calculation is based on Thailand GHG Management Organization’s guidelines.

A Foray into Europe’s Recycled Plastic Market

SCGC x Sirplaste

In response to the steady growth in global recycled plastic demand, SCGC has entered a rapidly growing circular industry by acquiring shares in Sirplaste, Portugal’s leading plastic recycling company, in which it will take part in the management of the company and the further development of high quality post-consumer recycled resin (PCR). SCGC will also be expanding its recycled plastic market across different regions and ensuring that the company consistently has new products on hand to introduce to the market to support the growing sustainable packaging market in the long term.

The high quality PCR resin introduced to the market by SCGC has been certified by the EuCertPlast standard – a European standard that verifies plastic waste traceability and ensures customers, brand owners, and consumers that the products they are using are made from post-consumer plastics derived from a traceable source, which means they help to reduce waste and truly contribute to the sustainability of the business and the environment.

This investment, in which include new technology and machinery, will enable Sirplaste to expand its high quality HDPE PCR production capacity by 25% or about 9,000 tonnes per year, which will put its annual PCR production capacity at over 45,000 tonnes by 2023, meeting the soaring demand in Europe and Africa.

SCGC x Kras

SCGC has signed an agreement to acquire Recycling Holding Volendam BV, or “Kras,” a leading waste management business in the Netherlands, which operates various plastic recycling businesses across the value chain from upstream to downstream, in line with SCGC’s business direction, which strives to be a leader as an integrated chemical business for sustainability by consistently developing green plastic innovations and strengthening the business by making a foray in Europe’s recycled plastic market with green polymer products.

Kras Kras’ main business is the collection and separation of used plastics and paper from households and industries. With over 65 years of experience, the company can source and collect 160,000 tonnes of plastic waste per year, mostly good quality materials from the industrial sector. In addition, Kras holds shares in the plastic recycling business REKS LLC, a PCR producer in Kosovo with a production capacity of 9,000 tonnes per year, which is slated to be doubled in 2023, as well as in Circular Plastics BV, which offers sustainable circular packaging and transport solutions in the Netherlands.

High Quality Odorless PCR from Mechanical Recycling for Packaging of Scented Personal Care Products

Made of domestically sourced, post-consumer plastic that has undergone a cutting-edge sorting and cleaning process for hygiene and safety, and treated with an odor elimination technology, this innovation, once formed into packaging, creates containers that have no unpleasant smell and thus lend themselves to personal care products that highlight the scents. In addition, the PCR resin has been certified by the Global Recycled Standard (GRS), meaning that the source of the raw material can be traced. SCGC has also collaborated with Lion to develop packaging made from this high quality odorless PCR resin.

Certified Circular Polyolefin Resin from Advanced Recycling

Hard-to-recycle used plastics are transformed into feedstock for petrochemical plants and reproduced into resin. The resulting resin has comparable properties and quality to virgin plastic and has been certified by the ISCC PLUS sustainability standard across the value chain. This innovation caters to the growing need of the food industry for green packaging and helps to reduce domestic waste accumulation.

RENEWABLE - Achieving Biocompostable and Resource Circulation

SCGC has developed bio-compostable compound resin that can readily be formed into biocompostable plastic bags and has most recently developed EcoBioPlas, an innovative additive that promotes biodegradability without impacting the forming process and the properties of the finished product. In addition, SCGC has joined hands with Braskem to study the feasibility of manufacturing bio-based polyethylene using renewable sources from agricultural products.

Bio-Compostable Compound: A new eco-friendly alternative

Because of its special properties, this innovation is ready to be extruded into films for the production of biocompostable plastic bags for household and industrial use, improving the convenience and efficiency of the production. Not only does it have all the properties required from manufacturers and users, it has also been certified by DIN CERTCO, a world-class institute based in Germany, to be industrially compostable at 60 Co, where it is transformed into carbon dioxide, water, and biomass in 180 days without leaving any contaminants in the environment.

EcoBioPlas: An innovative biodegradable additive for PP

This additive enhances biodegradability by catalyzing depolymerization of plastic into smaller molecules when exposed to light, heat, or moisture and inducing microorganisms to break down plastics into carbon dioxide, water, and biomass (in case of aerobic decomposition). The additive, thus, makes plastic more eco-friendly, without any adverse effects on the forming process and the mechanical properties of the plastic itself.

SCGC x Braskem join forces to advance bio-based polyethylene

SCGC and Braskem, a world-class bioplastic leader from Brazil, have signed a memorandum of understanding to conduct a feasibility study for an investment in a bioplastic manufacturing plant in Thailand to produce bio-based ethylene, which will serve as feedstock of bio-based polyethylene, or Bio PE, to meet the steady growth in bioplastic demand both in Asia and across the globe as well as promote the use of green plastics among eco-conscious consumers.

LSP is Vietnam’s first integrated petrochemicals complex and is a wholly owned subsidiary of SCGC. This project enjoys a distinct competitive advantage as it connects and integrates various chemical plants in Vietnam from upstream to downstream and incorporates advanced technology across the value chain to elevate operational excellence and enhance the safety and eco-friendliness of its production process, while also pursuing sustainable development in its business operations and placing emphasis on fostering growth alongside its environmental, social, and governance (ESG) responsibilities.

Situated in a location of vast potential only about 100 km away from Ho Chi Minh City, Vietnam’s main market and economic hub, LSP is adjacent to a deep seaport, which allows for convenient feedstock import and product export, and located near a large international container port, making it convenient to transport polymer products to the market.

For additional information : https://www.scgchemicals.com/kfair/k2022/lsp#present

Contact : scgchemicals@scg.com

SHINKOLITETM: Premium Acrylic Sheets for Better Living

SHINKOLITETM has been established through the partnership between SCGC and Mitsubishi Chemical Group Japan (MCG) as a world-class leader in chemical and acrylic sheet manufacturing that delivers innovative products and services to continuously meet the market demand. With the concept “Acrylic Solution Provider,” SHINKOLITETM caters to the functional needs of architects, designers, project owners, and general users through a diverse range of products that afford convenience, such as transparent awnings/garage roofs, acrylic railings, interior doors, acrylic partitions, interior décor, and façades.

SHINKOLITETM has been awarded an SCG Green Choice label for Climate Resilience and Thailand’s first and only acrylic sheet to be certified by the Thai Industrial Standard (TIS) No. 2685-2558, thus elevating the quality of the product and fostering confidence among users. Distinctive properties of SHINKOLITETM include the following:

- Heat insulation : SHINKOLITETM acrylic sheets can reduce infrared radiation by 50% and decrease the temperature underneath by 5 Co on average (based on lab test results), making the space cooler and preventing any burning sensation on the skin.

- Strong and durable : Because it is solid throughout, the sheet can withstand more impact, and is thus harder to shatter, than glass and offers greater safety.

- Lightweight : At the same thickness, SHINKOLITETM acrylic sheets weigh only half as much, thus reducing the amount of steel needed for support and the expense. In addition, because of the decreased load-bearing requirement, they are ideal for an extension that calls for lighter materials.

- Extra width and length : Thanks to the closed production system, all contaminants can be filtered out right from the raw material preparation stage, ensuring that the finished product is clean and has very little adulteration. In addition, because it is manufactured with continuous cast technology, the sheet can have a maximum width of 2,736 mm. and a maximum length of 6,000 mm., ideal for large advertisement signage or other applications requiring a large seamless surface. The sheet also has uniform thickness throughout and thus, when formed, yields a high-quality, aesthetically pleasing product.

- Chic and sleek : With a smooth and shiny surface, the transparent material imparts a sense of stylishness, lending itself perfectly to modern houses or hotels looking to incorporate an elegant clear roof in their structures.

For additional information: https://www.shinkolite.co.th/

Contact : SCG Contact Center โทร 02-586-2222

SHINKOLITETM x WINDSOR

As they are 50% lighter than regular glass panes, SHINKOLITETM acrylic sheets provide a perfect accompaniment for WINDSOR vinyl doors and windows and yield greater functionality.

-

Easier to open or close and thus friendly to residents of all ages

-

Safer as acrylic sheets can withstand 10 times more impact than glass panes of the same thickness

-

Longer lifespan as acrylic is lighter and exerts less load on the hardware and the moving parts

-

Easier to maintain as the acrylic sheet is resistant to crack and can be used and cleaned without worries

6. Food Packaging Solutions from SCGPSCGP

SCGP operates in pursuit of sustainable development and drives its businesses using an ESG (environmental, social, and governance) approach. It also seeks to grow its business through capacity expansion and through mergers and partnerships (M&P), including consistent investment in medical supplies and labware device, food packaging, and recycling businesses, to address current trends and meet customer needs with a diverse and comprehensive range of products, services, and solutions, in line with the “Evolve the Way of Life” brand promisetenet of SCGP.

In response to the increasing demand for sustainable packaging, SCGP has actively been expanding its investments in the packaging material recycling business through M&P. It has acquired 100% stake in Peute Recycling B.V., or Peute, the largest packaging material recycling company and distributor of paper and plastic raw materials in the Netherlands, and a 90.1% shareholding in Jordan Trading Inc., or Jordan, a trader of recovered paper (RCP) based in New York, USA, to enhance its packaging material recycling capabilities and strengthen its integrated packaging business.

SCGP Recycl: This business offers easy at-source waste separation solutions to maximize recycling. Consumers can easily take part in this initiative by taking cardboard boxes, aluminum cans, glass bottles, and plastic bottles to drop points near them at any of the venues of SCGP Recycle’s partners, such as department stores, housing estates, gas stations, and offices — a full list of which can be checked in the SCGP Recycle application. Thanks to an efficient, convenient, and trackable management system, consumers can be assured that their waste will be reutilized to the greatest advantage rather than incinerated or landfilled, which in turn helps to reduce the emissions of greenhouse gases, one of the primary causes of global warming.

rPET packaging and PIR (post-industrial recycled) resin plant pots : Produced by Duy Tan, a Vietnamese manufacturer of thermosetting plastic packaging, the products cater to the needs of consumers seeking to reduce plastic waste through systematic recycling.