An insidious pandemic of the new coronavirus disease 2019 (COVID-19) has profoundly disrupted the world, leaving people in distress and claiming hundreds of thousands of lives. The pandemic has reshaped the way people live. Everyone has to embrace the new normal lifestyle and social distancing while patiently waiting for the scientist and doctor to discover vaccines and treatments to defeat COVID-19.

Although the situation in Thailand has improved, it is undeniable that life after lockdown and ways people interact still put everyone at risk of infections. Back in the critical days where hospital’s healthcare workers faced a higher risk of infection, it was necessary to equip healthcare workers with enhanced safety measures to prevent adverse situations that might affect medical resources and capabilities to provide care for people.

SCG, an innovation development company, can never allow the doctors to work alone in this time of crisis. As a result, SCG has joined forces with the medical team to leverage expertise, reinvent products, and develop medical hardware exclusively to combat COVID-19. The effort is a way to harness Thai people’s ability to develop the never-before innovation in no time to fulfill the need on top of offering a practical solution.

Reinventing Medical Approach on Screening to Cope with an Arrival of COVID-19 by Doctors to “Modular Screening & Swab Unit” Developed by SCG

Dr. Somkiat Lalitwongsa, Director of the Rajavithi Hospital, revealed that the screening process for COVID-19 on the frontline was the main obstacle as it is unfeasible to distinguish suspected COVID-19 patients from patients with the common cold. The hospital came to a solution to set up an outdoor one-stop service as a screening checkpoint to prevent the virus from entering the hospital building.

“Rajavithi Hospital is among hospitals facing overwhelming demand for COVID-19 test. So, we have to establish an effective screening site to ensure safety for doctors when they come in close contact with patients to prevent further outbreaks. The SCG’s Modular Swab Unit helps facilitate safe swab operation as it can isolate suspected COVID-19 cases from regular patients with the common cold who must be treated separately.”

The screening unit at the one-stop service provides primary safety measures, but it cannot guarantee full protection for doctors. SCG has joined forces with the medical team to develop innovations to provide end-to-end protection throughout the process from the starting point, screening, testing, and treatment.

Mr. Nithi Patarachoke, President of Cement-Building Materials Business, SCG, said that the team at Cement-Building Materials Business, SCG, has observed and extracted the unfulfilled needs and worked with the hospital’s doctors to find the solution. The team has discovered that doctors and nurses working on the frontline combating and stopping the COVID-19 were in need of a standard screening facility with a good ventilation system to not only accommodates lower risk of infections for healthcare workers but also facilitate test operations, reduce patient’s waiting time, and cater to a rise in demand.

“After the team conducted assessment and observation at the hospital, the team developed the Modular Screening & Swab Unit, which integrates the modular technologies of SCG HEIM and Living Solution designed to maintain adequate air pressure and clean and safe air circulation with the air tightness system which keeps the unit sealed and prevent air migration. The technology offers effective pressure control in the unit. The technology can ensure better safety at work healthcare workers. About 70-80 percent of the structure is made in factories where the quality and the cleanliness of the units are under control throughout the manufacturing process. Healthcare workers will be in a clean room where the contaminated air will be barred to ensure a clean and safe environment. The suspected patients will be in a negatively pressurized room equipped with constant suction to prevent the virus from escaping to outside. Plus, the UV germicidal sterilizer is used after each use to ensure safety among healthcare workers.”

The Benevolence of His Majesty the King and Her Majesty the Queen Extended to People. Their Majesties Donated COVID-19 “Modular Swab Unit” to 20 Hospitals Nationwide.

His Majesty the King and Her Majesty the Queen have graciously donated “Modular Swab Unit,” as part of the royal relief project to support ventilators and medical equipment in an effort to curb the spread of COVID-19. Their majesties have granted financial assistance to allow SCG deploying Modular Swab Units in 20 hospitals nationwide. The initiative aims to increase the readiness to handle a second wave of COVID-19 in the future. The contribution has brought tremendous joy to doctors, nurses, healthcare workers, and the people who are highly appreciative of their majesties’ kindness.

RADM Kerdsak Virayodhin, Director of Somdej Phranangchaosirikit Hospital, Naval Medical Department, said, “At present, the hospital has to provide care for existing patients and accident-related cases of which we cannot fully identify the individual with COVID-19 infection. The process of the patient receiving the test will become the new normal in society. And this will help screen asymptomatic patients who may have carried the virus. This can help prevent infections among healthcare workers, and reduce the use of PPE suits, boosting confidence among workers who perform procedures on patients. This is indeed an immeasurable benevolence of their majesties who have donated the Modular Swab Unit to the hospital. This support will help strengthen the hospital’s capability and reduce the risk of infections for both workers and the people.”

Furthering Innovations: SCG Expands Innovation Series, Introducing “Mobile Isolation Unit” Easy to Install and Dissemble, Improving Access to Hospital in Remote Area

With a combination of the expertise in plastic material sciences, engineering and innovation design of Chemicals Business, SCG, and knowledge and experience of medical teams, the team has collectively developed the innovation with the goal of reducing the risk of transmission among healthcare workers while preventing the spread of the virus coming from patients and making it accessible in the remote area. As a result, the “Mobile Isolation Unit” is introduced with the great advantage of easy transportation, effortless installation, and lightweight, along with reducing the burden of procuring and using PPEs (Personal Protective Equipment). Doctors can work with comfort and be at ease while battling with COVID-19.

Mr. Tanawong Areeratchakul, President of Chemicals Business said, “Chemicals Business, SCG, has co-developed COVID-19 Mobile Isolation Unit with medical experts from three hospitals: Rajavithi Hospital, Ramathibodi Hospital and Hospital for Tropical Diseases. The effort is to make it most fitted with medical practices. The Mobile Isolation Unit series is made up of five main innovations, and its highlight is that the units can prevent the spread of the virus to medical professionals using an efficient air pressure system and the HEPA air filter system that can produce clean and safe air. Moreover, the units can be easily installed and removed and transported, as every piece of the equipment is strong and made of plastic, which is lightweight yet durable.”

The COVID-19 Mobile Isolation Unit series is made up of five main innovations:

1) Negative Pressure Isolation Room This special supplementary equipment is designed to fit emergency rooms, ICUs, or even patient rooms, in order to let doctors and nurses immediately treat patients with severe symptoms without the need to move the patient or other life support equipment.

2) Negative/Positive Pressure Isolation Chamber The chamber allows doctors and nurses to conduct swabs without direct contact with patients. Designed in a vertical cylinder shape, the chamber comes with an entrance that can be zipped open and close for ease of usage.

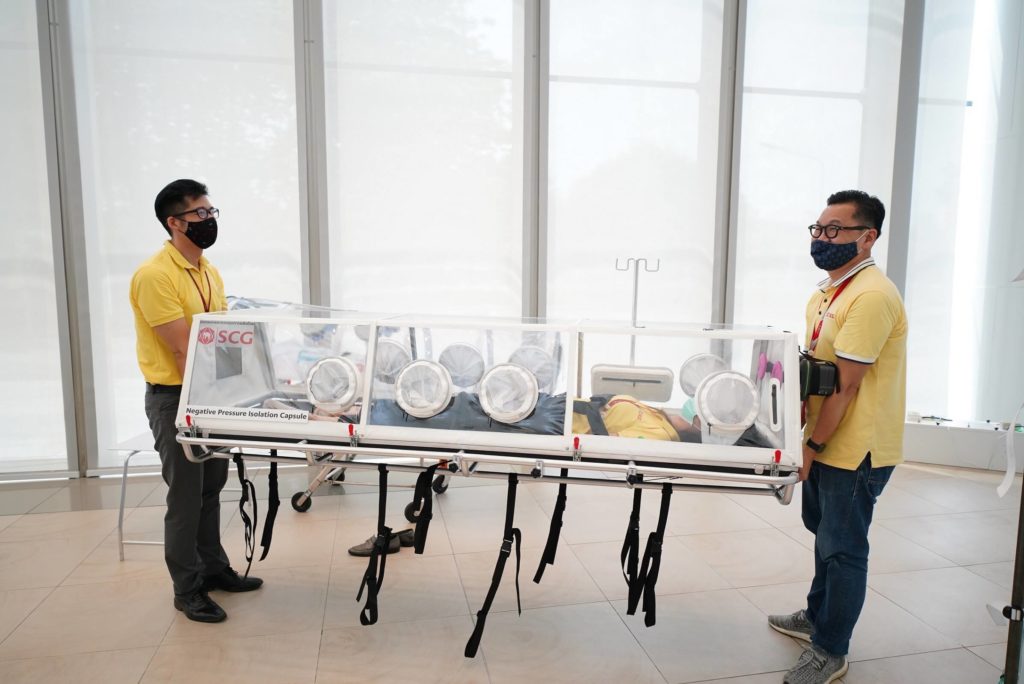

3) Patient Isolation Capsule This equipment helps prevent the spread of the virus during patient transportation.

4) Small Patient Isolation Capsule for CT Scan This equipment helps prevent the spread of the virus during patient transportation to the CT scan.

5) Dent Guard This equipment helps prevent the spread of the virus during dental work.

Assoc. Prof. Somboon Subwongcharoen, Head of Department of Surgery of Rajavithi Hospital , is among the first doctors to use the Negative Pressure Isolation Room in the emergency room said, “The design catalyst, material science, and design experts and engineering team of SCG developed the DIY (Do-it-Yourself) Negative Pressure Isolation Room and provided installation instruction which can remarkably be complete within one hour. This is like a renovation for the patient reception area without putting new investment. The equipment is mobile, which is practical for preventing the spread of the virus. It has a suction system to limit the transmission along with a rubber wall to reduce the risk of infection coming from the patient. The unit can be adapted for use in the field hospital to handle a potential surge in cases in the future.

Mr. Tanawong added that although all these five innovations are made of plastic, they are eco-friendly as they can be recycled and converted into raw materials after use. The product reflects the SCG’s product development philosophy that is in line with the Circular Economy where materials reaching the end of its life will be recycled and back in loops, limiting the amount of waste generated.

Plastic, when used at the right place and at the right time, can offer numerous benefits. It can protect medical professionals and help combat COVID-19. The products are invented and developed by Thai people in time of need.

No One Is Left Behind: Thai people, Government and Private Sector Joining Forces to Protect Healthcare Workers and Procure Equipment to Equip Doctors, Nurses in Fight with COVID-19

When it comes to a time of unprecedented crisis without response plan and the medical resources were scarce, hospitals across the country were in dire need of personal protective equipment to keep healthcare workers safe from infection. Thai people and the support from the government and businesses have coalesced in a concerted effort to procure medical innovations and equipment such as Modular Screening & Swab Unit, Mobile Isolation Unit, and Tele-Monitoring to fulfill the needs of healthcare workers in protecting themselves and patients from COVID-19.

Dr. Sumet Tantivejkul, Secretary-General of the Chaipattana Foundation said, “Her Royal Highness Princess Maha Chakri Sirindhorn has been concerned about Thai people who are struggling at the moment. Her Royal Highness has assigned the Chaipattana Foundation to be a channel for providing relief and assistance for people by procuring equipment and essential medical staples for COVID-19 care. The procurement is to support healthcare workers and meet the needs of all hospitals nationwide. The SCG’s Mobile Isolation Unit was first introduced to Crown Prince Yaha Hospital in Yala province. Apart from preventing the spread of the virus during medical treatments, innovation is easy to use as it can be conveniently installed and transported, which is suitable for hospitals in remote areas. The Coca-Cola business group in Thailand has supported the transportation of the equipment to the hospital.”

Mr. Chaovalit Ekabut, Executive Director of SCG Foundation, said, “SCG Foundation would like to be part of the “Care Together” effort to help Thailand get through this crisis. The foundation has donated over 50 million Baht to develop COVID-19 protective gear to enhance safety and facilitate medical professionals, patients, and their close contacts. Over the past few months, SCG has delivered innovations to large hospitals handling overwhelming patient load. The effort aims to boost confidence among doctors and nurses and help them combat COVID-19 with safety and get through the crisis.”

Furthermore, Mr. Kalin Sarasin, chairman of the Thai Chamber of Commerce and Board of Trade of Thailand, said. “The Thai Chamber of Commerce and Board of Trade of Thailand and the private sector realized the severity of the COVID-19 pandemic and is ready to assist Thai people facing the crisis. It has urged a network of Thai Chamber of Commerce across the country, Provincial Chamber of Commerce, trade associations, International Chamber of Commerce, University of the Thai Chamber of Commerce, members and well-wishers to donate fund for procuring essential medical equipment to assist doctors and nurses working on the frontline handling patients and COVID-19. The Thai Chamber of Commerce has donated ten ‘Negative Pressure Swab Unit’ developed by Prince of Songkla University and CPAC Construction Solution to ten hospitals with high patient load in seven southern provinces of Thailand. It highly hopes that collaboration from the business sector can empower Thailand to get through the crisis.”

All these innovations are created to serve a specific purpose to address urgent needs on a short-term basis. It is solidarity to work to help the country get through the COVID-19 crisis, and it is an opportunity to develop a locally-made medical innovation prototype that can be further developed to meet the global demand. The effort is to cater to growing global health trends. But above all, the COVID-19 pandemic in Thailand cannot be resolved today if lack of cooperation and generous contribution of Thai people who help one another during difficult times where everyone is faced with unexpected hardship.

บทความนี้มีประโยชน์หรือไม่ ?

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.