Environmental

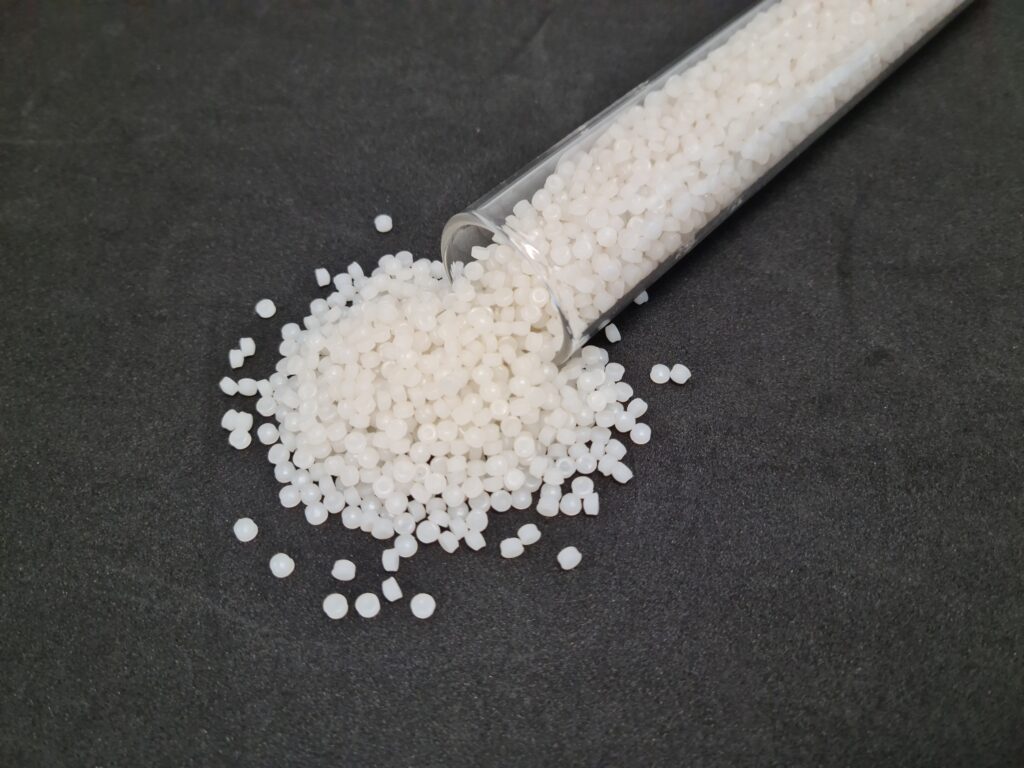

SCG GREEN POLYMER™

- Reduce: Offer solutions to reduce resources consumption and maximize resource efficiency via the SMX™ Technology for high-quality plastic resin production. This process supplies special HDPE that balances high strength and stiffness. It results in less plastic for product manufacturing whilst maintaining the strength level. With such attributes, the technology unlocks various types of products ranging from lightweight CSD caps, high-impact films for industrial purposes, to SCG Green Choice standard extra-strong large chemical tanks. Above all, the item better reduces greenhouse gas emissions in the production process when compared to general plastic resins.

- Recyclable: The solutions are designed for recyclability, shifting from prevalent yet difficultly recycled multi-material packaging to mono-material PE or PP packaging which allows efficient recycling while embracing functional and aesthetic attributes aligned with brand owner needs.

- Recycle: The solution facilitates the recycling of Thailand’s post-consumer plastics, thus, reducing waste and resources consumption. In the procedure, sorted and cleaned post-consumer plastics are processed to become high-quality Post-Consumer Recycled Resin: PCR resins possessing qualities that meet consumer demands. The PCR resins are certified by the Global Recycled Standard (GRS), a global standard for the sources of raw materials for the production of recycled plastic resins. Also, in the determination to develop and expand the recycled plastic market to other regions, SCG Chemicals has collaborated with local and international expert partners in recycling. The venture involves Teamplas, Thailand’s leading manufacturer of recycled plastic pellets for 30 years, Suez, Europe’s forefront in recycled plastics, and Sirplaste, the largest plastic recycler in Portugal.

Additionally, the plastics that may have not been properly sorted are processed in the Advanced Recycling technology or chemical recycling. Here, they turn to recycled feedstock in petrochemical plants for plastic resins production. Their properties are on par with virgin plastics and are accredited in the ISCC PLUS standard by the International Sustainability and Carbon Certification (ISCC). This is Thailand’s first company to obtain this leading internationally acclaimed sustainability certificate. - Renewable: The solution that delivers bio-compostable compound plastics. This is SCG Chemicals’ ready-made formula which can be promptly extruded into film products for household and industrial use, adding to the molding convenience and efficiency. Moreover, they offer prime attributes that target consumer needs and have been certified as being bio-compostable compound by the world’s leading institution, DIN CERTCO in Germany. In addition, another solution to reduce the dependence on depleting fossil-based resources in the plastic production process is shifting to bio-based resources which can be replaced with plantations. This will contribute to reducing greenhouse gas emissions and alleviate the impact on global warming. At present, there are collaborations with Braskem, the world’s bioplastic leader in Brazil, for a feasibility study of ventures to build a bio-ethylene plant for bioplastic production in Thailand.